Description

Continuous Casting Machine

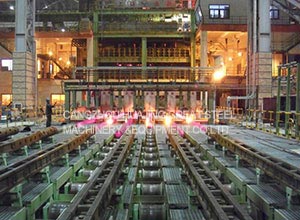

Continuous casting (CC) is a method of producing an infinite solid strand from liquid steel by continuously solidifying it as it moves through a CCM. It is the predominant process route in a modern steel plant which links steel making and hot rolling. A typical section and plan view of a

CCM is shown in Fig 1.

Fig 1 Typical section and plan view of a CC machine

Types of continuous casting machines

CC machines have evolved from the strictly vertical type of machine to curved machines in order to limit the installation height while still using high casting speeds. In recent years, CC machines of more sophisticated mechanical design are being constructed. These machines apply several techniques for achieving higher casting speeds and higher outputs and are with progressive straightening or progressive bending over a liquid core.

Simple vertical CC machine with a straight mould and cutoff in the vertical position

Vertical CC machine with a straight mould along with single point bending and straightening

Vertical CC machine with a straight mould along with progressive bending and straightening

Bow type machine with curved mould and straightening

Bow type machine with curved mould and progressive straightening

In all cases, the bending and straightening is usually carried out in one or several steps. Multistep bending and straightening reduces the mechanical stresses and reduces the risk of strand cracking. The first CC machine which was built up for CC of liquid steel was a simple vertical CC machine. Then later the development led to many kinds of CC machines with various ways of bending and straightening. The main objective for these developments have been to construct lower and simpler CC machines with smaller need for space, lower investment costs, and high flexibility in production and maintenance. One of the main issues with a vertical CC machine is that the distance between the mould and the point of cutting is limited. Due to this the casting speed is low and low speed means low production rate. The advantage of the vertical CC machine is that there is no bending or straightening of the strand. In the case of large strand sizes, the stress caused by the ferrostatic pressure of the liquid steel inside the strand can lead to bulging of the solidified strand shell.

The high bulging can lead to the formation of severe defects like segregations and cracking. It is therefore very important to support the strand sufficiently to avoid bulging. The higher is the machine, the bigger is the risk for bulging. This is also one reason for the development of the lower machines, i.e., bent or bow-type casters.

One important characteristic in continuous casting is the removal of nonmetallic inclusions from the liquid steel. Owing to their lower density compared to the liquid steel, the inclusions are able to float up from the liquid. In the straight CC machines, the inclusions can float up more easily to the meniscus (liquid surface near the mould wall) than in the bow type CC machines. This is because in the bow type CC machines some inclusions can attach to the inner arc of the strand shell, when they are flowing up. This can be seen as a higher amount of inclusions but also as an uneven distribution of the inclusions in the as cast strand. So, the vertical or vertical bending type CC machines have the advantage that inclusions can float up better to the meniscus than in bow type CC machines. These days, the most common CC machine type is the bow type with curved mould. The strand leaves this curved mold in an arc without the need for bending after the mould and just with straightening at the lower part of the CC machine. In the case of larger strand, especially with slabs, also vertical bending CC machines are today more and more popular, because of the increasing need for cleanness. It is anyhow important to know that many things other than the CC machine design affect the cleanness and steel quality.

The CC machines are normally named according to the strand dimensions such as billet, bloom, and slab CC machines etc. There are also CC machines to cast rounds and other shapes like beam blanks.